The smart Trick of Water Purifier For Well Water That Nobody is Talking About

Table of ContentsGetting My Water Purifier For Well Water To WorkThe Basic Principles Of Water Purifier For Well Water Getting My Water Purifier For Well Water To WorkGet This Report on Water Purifier For Well Water

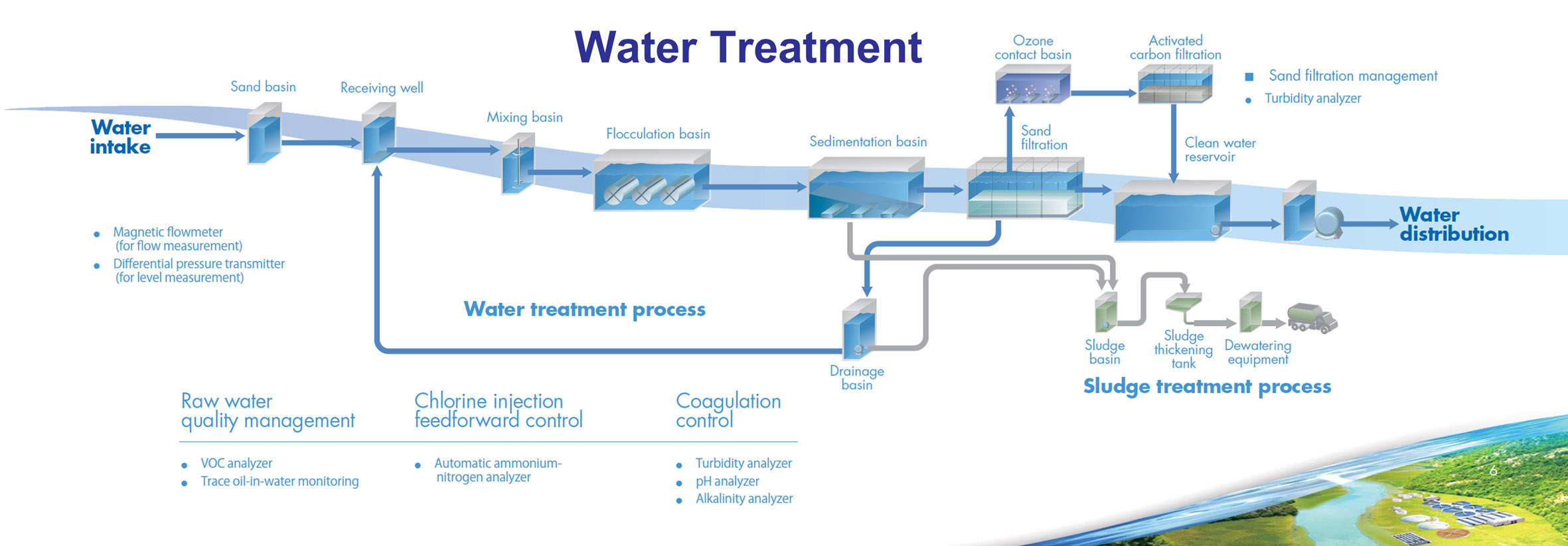

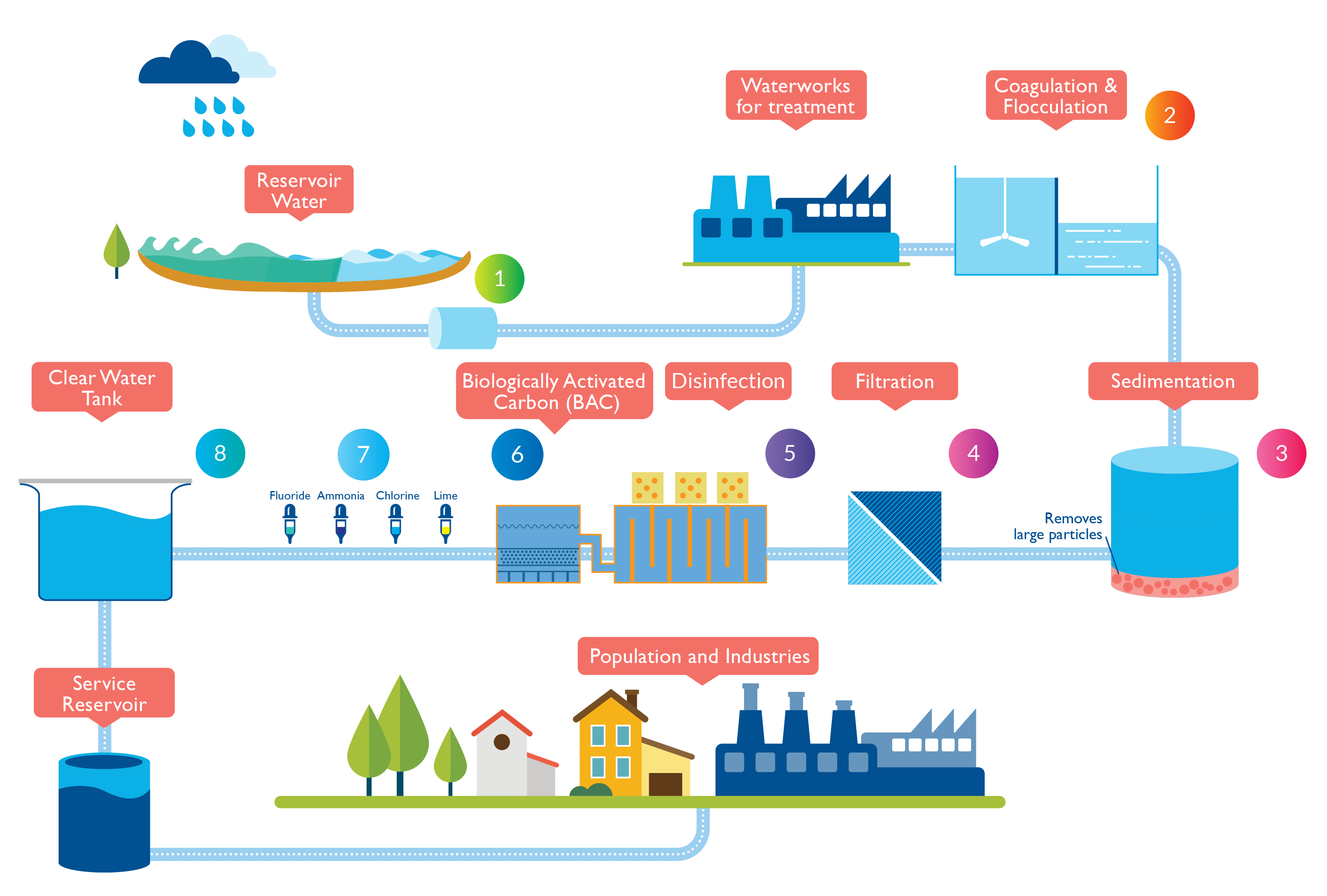

A phosphorous substance is included in assist control deterioration of pipes. This assists stop lead and copper that may be existing in pipes from leaching right into the water. As the water leaves the plant, ammonia is included in alter the chlorine to chloramine, a disinfectant that keeps a recurring in the distribution system versus microbial contamination.All chemicals that are added are accredited food grade, safe for use in foods. Dealt with water is stored in deep underground containers as well as also moves by gravity to pumping stations and also right into the circulation system. The circulation system consists of 1,960 miles of water pipe ranging in diameter from 4" to 60".

Removal of taste as well as smell substances from the water.: Softens the water.: Filtration to get rid of little particles and sanitation to eliminate viruses as well as microorganisms, and also ensure an improper atmosphere for infection and bacteria growth throughout the distribution system.

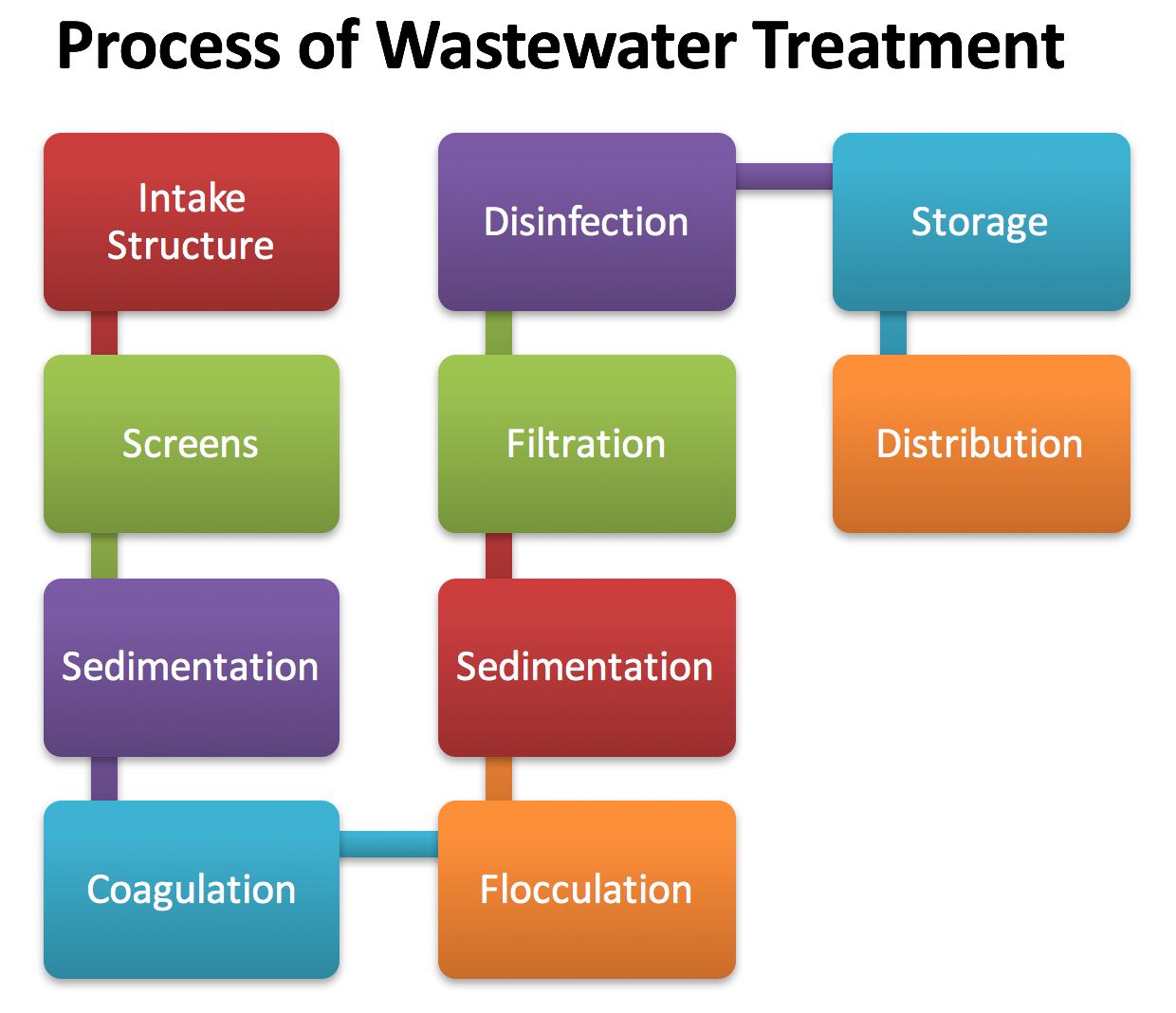

8 Phases of the Wastewater Process Phase One Bar Screening Elimination of big things from the influent to avoid damages to the facility's pumps, valves and also other equipment. The process of dealing with and recovering water from wastewater (any type of water that has been used in residences, such as flushing bathrooms, washing recipes, or bathing, as well as some water from commercial use as well as tornado drains) begins with the expectation that after it is treated it will be tidy adequate to reenter the setting.

Fascination About Water Purifier For Well Water

According to the EPA, The Tidy Water Act (CWA) develops the basic framework for regulating discharges of pollutants right into the waters of the USA and also regulating top quality standards for surface waters. Under the CWA, EPA establishes wastewater criteria for sector. The EPA has likewise established national water top quality criteria recommendations for pollutants in surface waters.

This begins in the oygenation storage tank. The main function of the oygenation storage tank is to pump oxygen right into the storage tank to encourage the malfunction of any kind of organic product (and the development of the germs), in addition to make certain there suffices time for the organic material to be damaged down.

An Unbiased View of Water Purifier For Well Water

This process is taken care of to supply the best problems for microbial development. Oxygen gas [O2] levels listed below 2 ppm will certainly kill off the bacteria, reducing effectiveness of the plant. Liquified oxygen tracking at this phase of the plant is vital. Ammonia and also nitrate measurements are typical to determine just how efficient the germs are in transforming NH3 to N2.

Phase Five Secondary Clarifier Treated wastewater is pumped into an additional clarifier to allow any type of staying organic debris to resolve out of cured water circulation. As the influent exits the aeration procedure, it moves into a secondary clarifier where, like the primary clarifier, any kind of extremely little solids (or fines) sink to the base of the storage tank.

Component of this activated sludge is gone back to the oygenation storage tank to increase the my company bacterial concentration, aid in breeding, and speed up the malfunction of organic material. The unwanted is thrown out. The water that streams from the secondary clarifier has considerably minimized organic material article source and must be coming close to anticipated effluent specs.

With the improved focus of germs as component of the aeration phase, there is a need to evaluate the outgoing effluent for germs existence or absence as well as to disinfect the water. This makes sure that greater than specified focus of germs are not launched right into the atmosphere. Chlorination is one of the most typical as well as low-cost type of sanitation yet ozone and also UV sanitation are likewise increasing in appeal.

Getting My Water Purifier For Well Water To Work

After enough time, particles stick to each various other and also become larger bits, or, floc, which is prone to resolve in water. This process of floc formation is called flocculation. To help in the flocculation of bits, an anionic polymer is added in the blending area of the cone. Clarification of water is accomplished by the seperation of put on hold solids from water by gravity.

The cleared up water actions up gradually, eventually overlooking the effluent weir to the cone electrical outlet as well as on the to filters for additional treatment. The water plant incorporates a solitary stage lime softening operation to remove solidity. Hardness is brought on by the presence of liquified bivalent and polyvalent metal ions, mostly calcium and also magnesium.

This is included both in the clearwell as well as the high solution discharge as water goes into the distribution system. 2 mg/l is usually desirable in important site the plant tap.